Factory Automation

Products

Software Solutions

- MELSOFT Gemini 3D Simulator

- MELSOFT VIXIO Visual Inspection Software

- ICONICS Solution Suite

- EcoAdvisor Energy Saving Support Software

MELSOFT VIXIO - Transforming Visual Inspection

Results in 15 Minutes

Designed for compatibility

Effortless Quality Control

What is MELSOFT VIXIO?

We work hand-in-hand with our clients to tackle the most common challenges in visual inspection, including:

- Labor shortages increase the burden on inspectors

- Inconsistencies in inspection quality due to generational shifts in the workforce

- Rising overdetection rates even in rule-based inspection processes.

Here's how you can implement MELSOFT VIXIO into your inspection process

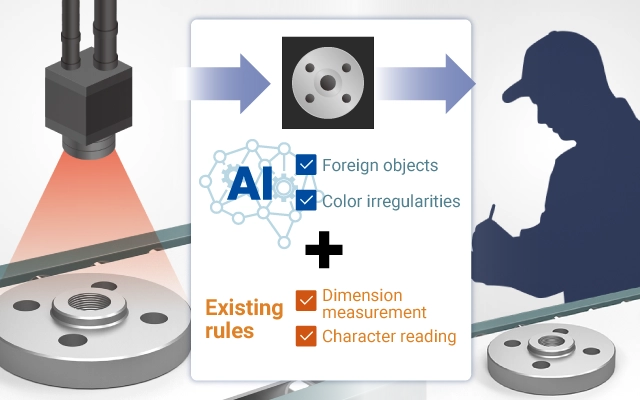

Enhance Quality Detection with AI pattern recognition

Minimise task labour with primary screening

Double check by AI and human eyes

The introduction of doublechecking reduces the risk of overlooking defective products and ensures consistency of quality between operators.

MELSOFT VIXIO features

Introducing our cutting-edge software, designed to revolutionise factory automation with advanced technology and user-friendly features. Whether you seek efficiency, ease of use, or comprehensive monitoring, our solution delivers unparalleled performance.

Key features include:

- High-speed, high-precision AI ideal for factory automation.

- Simple operation settings that require no knowledge or programming expertise.

- Improved traceability for enhanced monitoring and control across production.

- Works with your set up of choice – MELSOFT VIXIO works with many kinds of IPC, Graphic Cards or Cameras.

| AI introduction challenges | With MELSOFT Vixio |

| Requires large amounts of images featuring good quality vs defective products to create accurate, precise AI models suitable for production. Generating AI models requires extensive preparation, making the process time-consuming and inefficient. | Quickly introduce AI into production, and generate AI models effortlessly with high-speed, high-accuracy solution, requiring a minimal setup. |

| Even if an AI model could be generated implementing it in the system requires specialised programming. | Easily set up tasks at the machine in a low-code, flowchart format. Handle everything from model creation to monitoring in one tool. |

| Keeping track of data is difficult because it is stored in different places, using different tools. | Complete batch traceability now combines inspection times, control data, images, and results in one accessible system – improving quality control and process efficiency. |

Operation processes

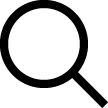

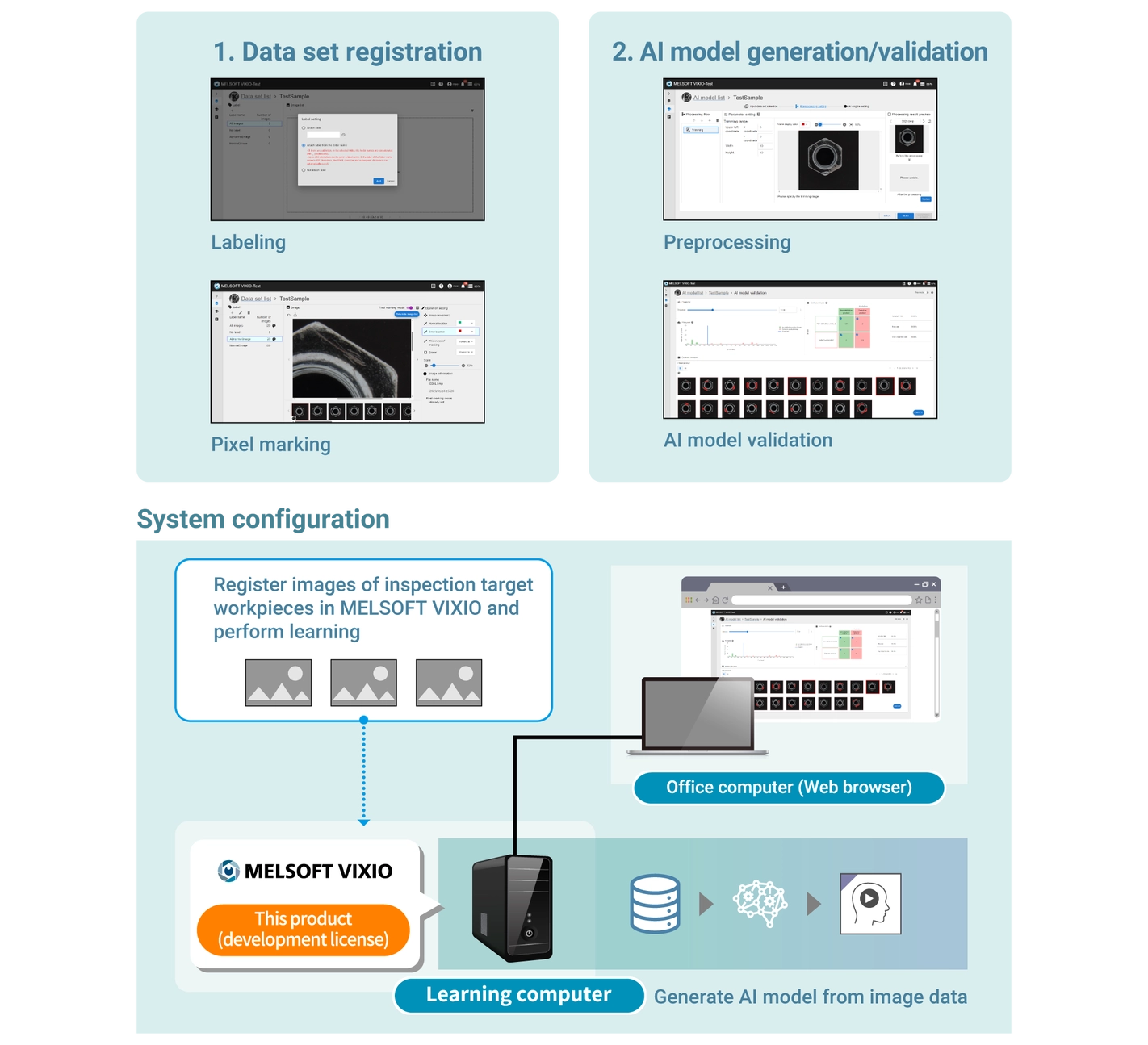

Learning phase

Step 1: Organise & Categorise

Prepare images of both good and bad quality products and categorize them accordingly. You can use existing archived images or installing a camera on the production line to capture real-time images during production.

Step 2: Preprocess Images

Adjust the images to optimize them for AI analysis. You need to crop out irrelevant areas to focus only on the necessary parts to improve AI results.

Step 3: Create an AI Model with one click

Start the creation of the AI model. The AI utilises a subset of the provided images to train the model, and another subset to validate its performance. This streamlined process ensures the swift development and deployment of the AI for product quality analysis, allowing for transparent evaluation of its effectiveness and performance.

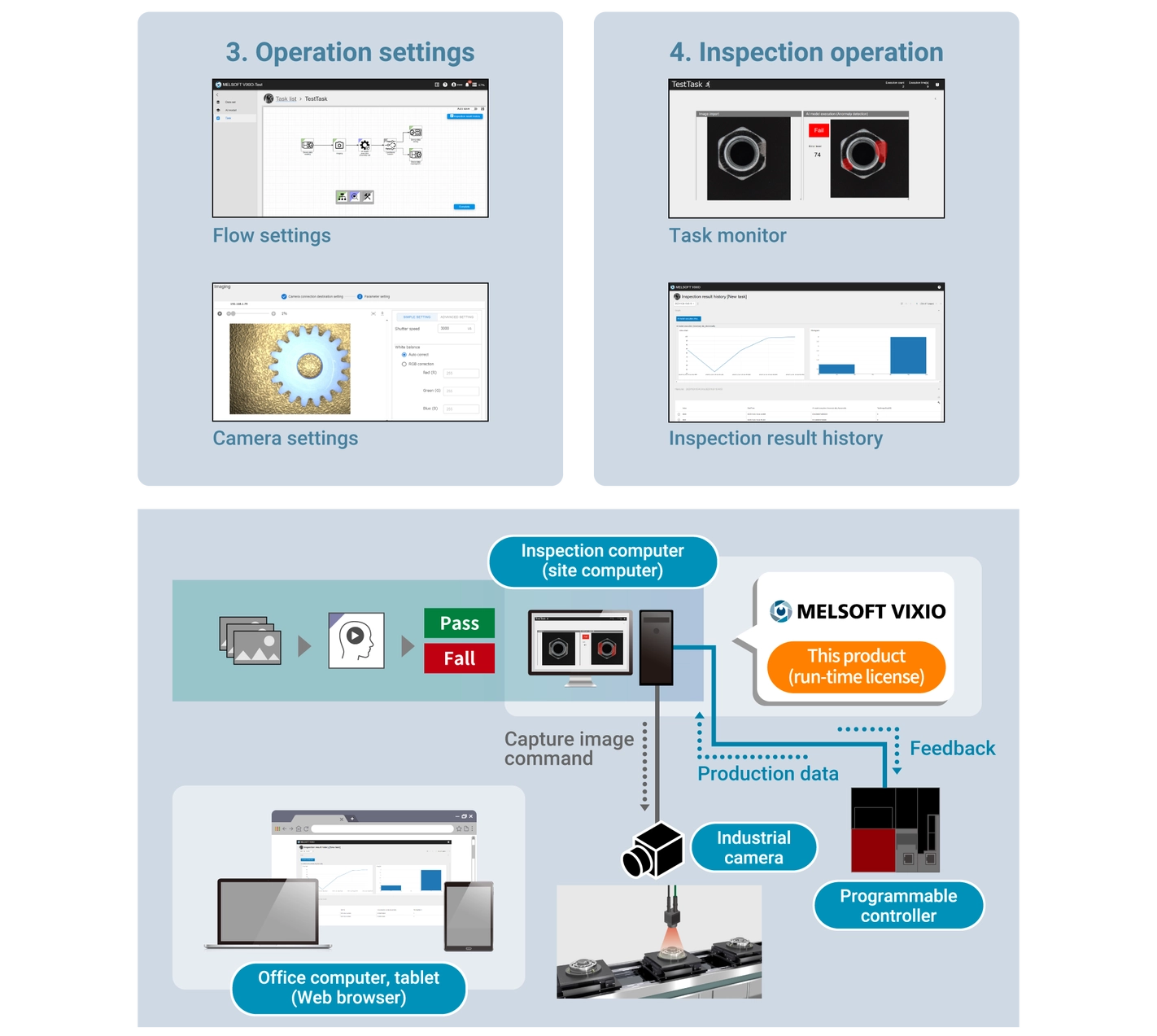

Inspection phase

Step 4: Configure the Task

Benefit from the pre-designed templates in low-code platforms to effortlessly configure the hardware and software setup. Define the interactions between the Programmable Logic Controller (PLC), MELSOFT VIXIO, and camera with ease. Direct integration of GigE Vision® cameras allows easy configuration and fine-tuning.

Step 5: Real-time Operation on the Production Line

Initiate the task on the production machine to commence real-time quality analysis. Gain immediate access to a live heatmap visualization of product quality, providing instant insights into production performance. Seamlessly track inspection history for comprehensive traceability functions, ensuring continuous improvement and quality control.

How to use MELSOFT VIXIO?

Mitsubishi Electric released AI Visual Inspection Software, MELSOFT VIXIO.

System Requirements

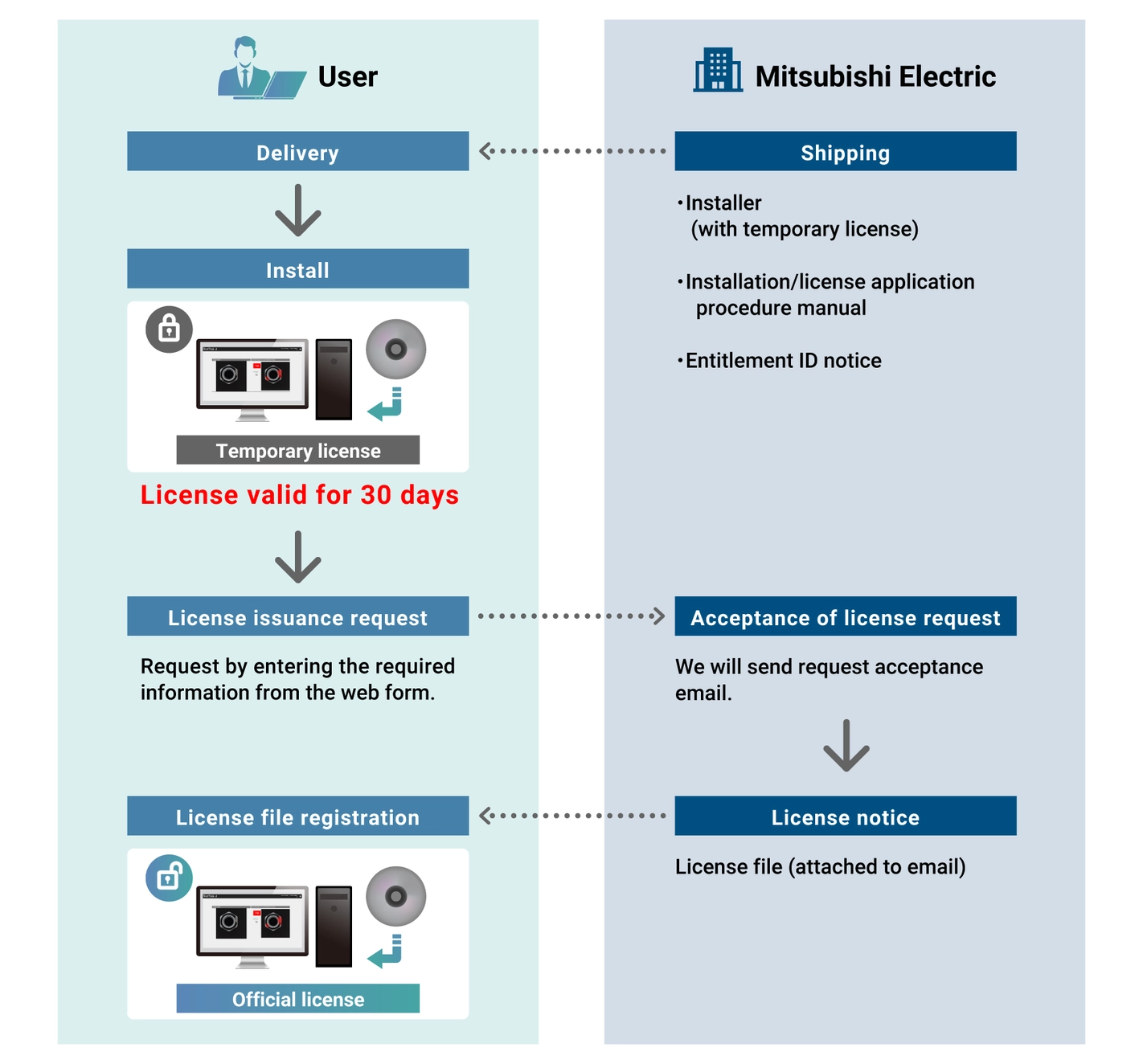

License system

Development license*

712272 – MELSOFT VIXIO Visual Inspection Software; Development license; DVD

| Period of use | Remarks |

|---|---|

| 1 year | All functions can be used |

| Item | Recommended | Minimum |

|---|---|---|

| CPU | Intel® Core-i7™ 9th generation (October 2018) or higher | Intel® Core-i5™ 9th generation (October 2018) or higher |

| GPU | NVIDIA GPU Ampere Architecture or higherMemory: 8 GB or more | NVIDIA GPU Pascal™ Architecture or higherMemory: 6 GB or more |

| Memory | 32 GB or more | 16 GB or more |

| OS (64-bit version) | Microsoft® Windows® 10 Version 21H2 or later (Pro, Enterprise)Microsoft® Windows® 11 Version 21H2 or later (Pro, Enterprise) | Microsoft® Windows® 10 Version 21H2 or later (Pro, Enterprise)Microsoft® Windows® 11 Version 21H2 or later (Pro, Enterprise) |

| Free storage space | 512 GB or more | 256 GB or more |

Run-time license*

712273 – MELSOFT VIXIO Visual Inspection Software; Runtime license; DVD

| Period of use | Remarks |

|---|---|

| Perpetual (one-time purchase) | Functions other than AI modelgeneration can be used |

| Item | Recommended | Minimum |

|---|---|---|

| CPU | Intel® Core-i7™ 9th generation (October 2018) or highe | Intel® Core-i5™ 9th generation (October 2018) or higher |

| GPU | NVIDIA GPU Pascal™ Architecture or higherMemory: 6 GB or more | NVIDIA GPU Pascal™ Architecture or higherMemory: 4 GB or more |

| Memory | 16 GB or more | 8 GB or more |

| OS (64-bit version) | Microsoft® Windows® 10 Version 21H2 or later (Pro, Enterprise)Microsoft® Windows® 11 Version 21H2 or later (Pro, Enterprise) | Microsoft® Windows® 10 Version 21H2 or later (Pro, Enterprise)Microsoft® Windows® 11 Version 21H2 or later (Pro, Enterprise) |

| Free storage space | 256 GB or more | 128 GB or more |

*:Node-locked license for one computer

Specifications

| Item | Development License | Run-time License |

|---|---|---|

| Number of projects | 16 projects/computer | 16 projects/computer |

| Number of users | 16 users/computer | 16 users/computer |

| Number of sets | 16 sets/project | – |

| Number of registered images | 10,000 images/set | – |

| Registrable image formats | jpg, jpeg, png, bmp | – |

| Registrable image size | Max. 10,000 pixels horizontally and vertically | – |

| Number of sets | 16 sets/project | – |

| Number of simultaneously executable learning processes | 8 models/computers *1*2 | – |

| Number of sets | 16 sets/project | 16 sets/project |

| Number of simultaneously executable tasks | 4 tasks/computer | 4 tasks/computer |

| Number of executable AI | 8 models/tasks *1*3 | 8 models/tasks *1*3 |

| Number of connectable cameras | 8 units/computer *4 | 8 units/computer *4 |

| Number of connectable programmable controllers | 8 units/computer | 8 units/computer |

*1: 4 models each for anomaly detection and defective point detection.

*2: Defective point detection uses 2.4 Gbytes of GPU memory per model.

*3: Tasks using defective point detection use 2.4 Gbytes of GPU memory per task.

*4: When multiple cameras are connected, phenomenon such as noise may occur in images due to resolution or network conditions. It is recommended that network cards be separated.

Connectable industrial camera specifications

| Hardware standards | Software standards |

|---|---|

| Conforms to GigE Vision® (Ver. 2.0) | Conforms to GenICam™ (Ver. 3.2.0) |

Note 1: For information on usable industrial cameras, please refer to Technical Bulletin FA-A-0419.

Note 2: “Connectable” means the following:

· Camera-side parameters (exposure time or white balance) can be adjusted in this product.

· Image capture command can be issued directly by this product.

Since it is possible to browse to a folder on the computer and perform AI inspection on stored images, cameras which do not meet the above specifications can also be used.

How to install

- Home

- Products

- Software Solutions

- Visual Inspection Software MELSOFT VIXIO