- Solutions

- e-F@ctory Overview

- Edge Computing

- IQ Platform

- FA Integrated Network

- FA Integrated Engineering Software

Inquiries

![]() e-F@ctory Overview

e-F@ctory Overview

![]() Edge Computing

Edge Computing

![]() IQ Platform

IQ Platform

![]() FA Integrated Network

FA Integrated Network

![]() FA Integrated Engineering Software

FA Integrated Engineering Software

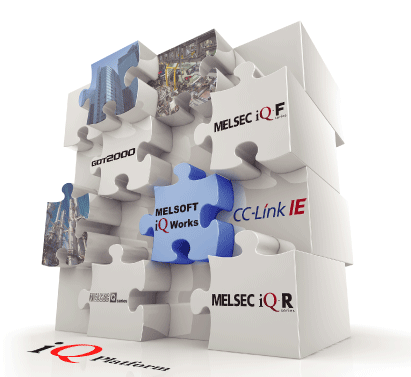

iQ Platform

Controller and HMI

Advanced, high-speed integrated controllers

The iQ-Platform realizes consolidated controllers on one common platform. Various different controllers responsible for different aspects of automation control can be used together on one high-speed system bus. The various control CPUs utilize high-speed data communication via the backplane, further reducing cost as additional networks are not required and improving performance owing to the platform’s large data bandwidth capability.

MELSEC iQ-R Series

* TCO: Total cost of ownership

By integrating MELFA robots, it is possible to leverage communication with other controllers and HMI utilizing the multi-CPU capability and improve overall machine productivity.

MELSEC iQ-F Series Programmable controller

OT2000 (HMI) Series

The GOT2000 improves productivity through its multiple advanced functions. The HMI can act as a seamless interface to other controllers within the production line, monitor production values, and offers easy-to-use multi-touch gesture operability. A high-resolution display enables viewing information clearly even when at a high zoom level.

- page top

- Edge Computing Products

- FA Sensor

- Drive Product

- Visualization

- Industrial Robots

- Low-Voltage Power Distribution Products

- Power Monitoring Products