MELIPC MI3000

- Easily visualize shop floor with GT SoftGOT2000

- Use various functions of GT SoftGOT2000 on a panel computer

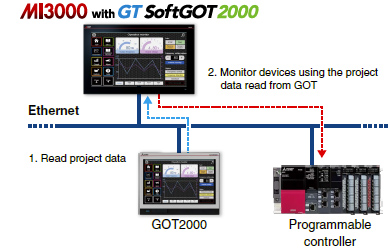

- Interaction with GOT2000

- Interaction with Windows® applications

- OPC UA client support for data collection and monitoring of various devices

- Easily create project data

- Specifications of GT SoftGOT2000

Easily visualize shop floor with GT SoftGOT2000

| MI3315G-W | MI3321G-W | |

| OS | Windows® 10 IoT Enterprise 2016 LTSB (64 bit) | |

| MPU | Intel® Core™ i3-6100U 2.30GHz (Dual Core) | |

| Screen size | 15″ | 21.5” widescreen |

| Resolution | XGA : 1024 × 768 dots | Full HD : 1920 × 1080 dots |

| Display color | 16.77 million | |

| Touch panel type | PCAP (Projected Capacitive) | |

| Main memory | 8GB | |

| Internal storage | 2001-03 | |

GT SoftGOT2000 pre-installed

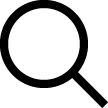

GT SoftGOT2000 is pre-installed*1 on MI3000. Various industrial devices can be directly connected*2 and monitored in the same way as GOT2000 Series. The data collected by Edgecross can also be monitored.

Use various functions of GT SoftGOT2000 on a panel computer

Alarm display

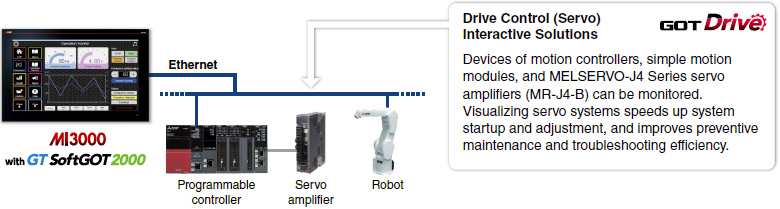

GT SoftGOT2000 displays communication errors (system alarms) of controllers and user-created alarms (user alarms).

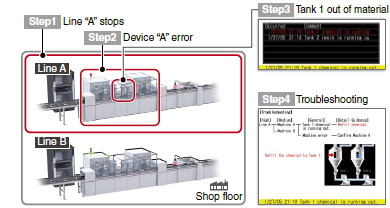

Operation log

GT SoftGOT2000 records the operation information, such as “what, when, and how” of an operation performed, in chronological order in a USB memory.

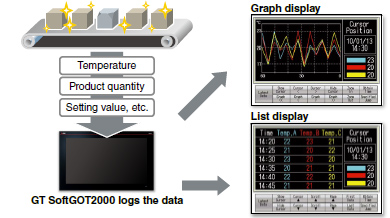

Logging & Graph/List

GT SoftGOT2000 collects the data from programmable controllers and other devices and displays the collected data in a historical trend graph and list.

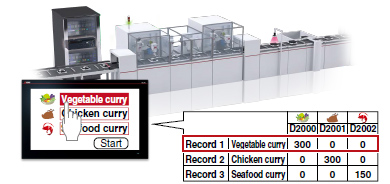

Recipe

GT SoftGOT2000 saves the recipe information (device values) such as material blend and machine conditions.

You can change the recipe on the GT SoftGOT2000 and write it to a programmable controller to quickly perform the changeover.

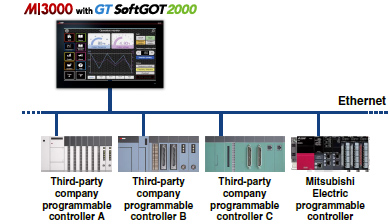

Multi-channel [ Supported in May 2019 ] [NEW]

Up to four channels of industrial devices can be monitored via Ethernet on a single module of GT SoftGOT2000. With this function, you can flexibly configure systems and visually check devices.

Operability

Interaction with GOT2000

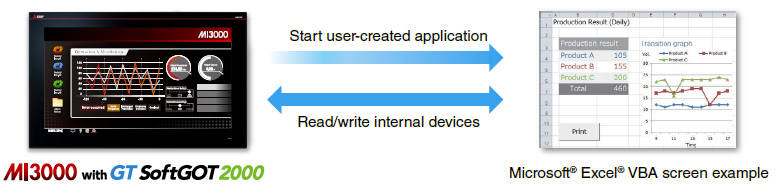

Interaction with Windows® applications

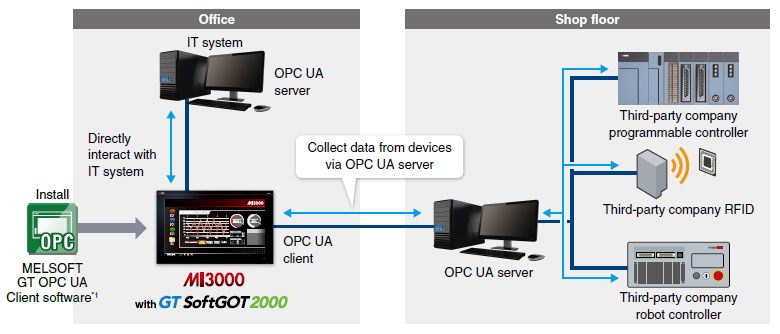

OPC UA client support for data collection and monitoring of various devices [ Supported in May 2019 ] [NEW]

OPC UA (OLE for Process Control Unified Architecture):

a highly reliable, open international standard for industrial communication that enables data exchange among devices from multiple vendors on different operating systems.

*1. It is required to install MELSOFT GT OPC UA Client software on a personal computer. For more information about how to obtain the software, please contact your local sales office.

To use the functions with [NEW] mark, it is required to update GT SoftGOT2000 to version 1.215Z or later.

Easily create project data

Creating screens is easy

Creating screens is easy

The display screen is created with GT Designer3.

By converting the GOT type to MI3000, the project data for GOT2000 can be used as is. Ready to use sample screens are also available.

Specifications of GT SoftGOT2000

| Item | Description |

| Resolution | 640 to 1920 × 480 to 1200 |

| Display color | 65536 colors |

| Display language | At initial startup: English*2 |

| Connection type*1 | Ethernet connection, direct CPU connection, serial communication connection, CC-Link IE Controller Network connection,CC-Link IE Field Network connection, MELSECNET connection |

*1 Required devices vary depending on the connection type. For the details, please refer to the GT SoftGOT2000 Version1 Operating Manual

SH-081201ENG-AG

*2 By switching display languages, Japanese and Chinese (Simplified) can be displayed. To upgrade the software version, use the English version of the upgrade software.

- For the system configuration of the GT SoftGOT2000, please see here.

* For obtaining GT SoftGOT2000, please contact your local sales office.

- Edge Computing Products

- FA Sensor

- Drive Product

- Visualization

- Industrial Robots

- Low-Voltage Power Distribution Products

- Power Monitoring Products